THE NORTH FACE

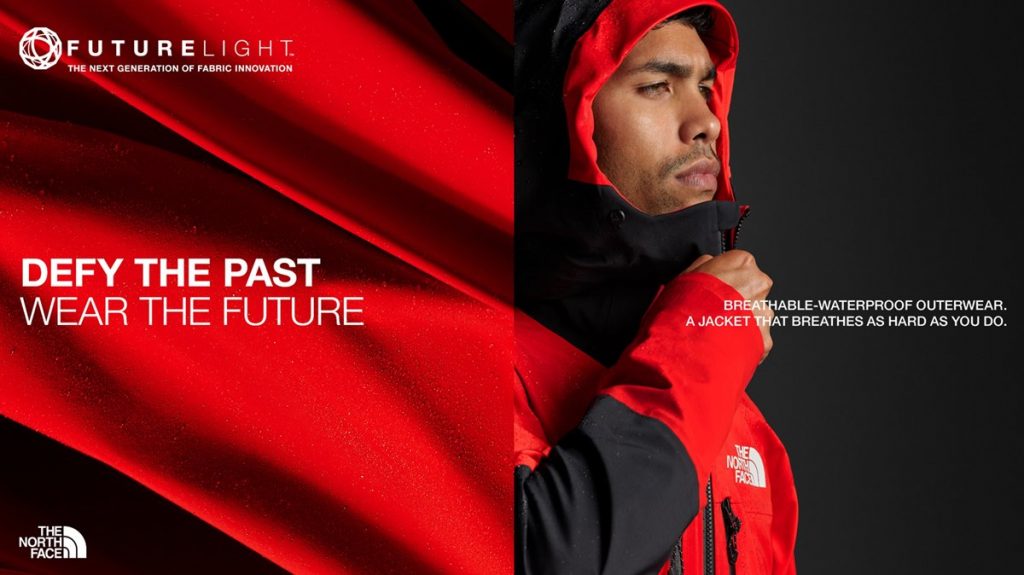

Resets Outerwear Expectationswith FUTURELIGHT™ Apparel Launch

New, proprietary material increases performance and breathability

of the brand’s waterproof gear

The North Face changed the future of the outerwear industry today with the unveiling of FUTURELIGHT™ jackets, pants and bibs in its Summit Series™, Steep Series™ and Flight Series™ collections. Developed using innovative nanospinning technology, FUTURELIGHT™ will offer first-of-its-kind breathable, waterproof protection.

The concept for FUTURELIGHT™ was born in the mountains out of specific requests from The North Face global athlete team looking for increased performance and breathability in their waterproof gear. Determined to reset the expectation that waterproof product is uncomfortable, heavy and stuffy, The North Face commenced a multi-year journey to create a waterproof fabric that’s not only soft, light, flexible and comfortable – but also durable and sustainably designed. After three years of research, product development and extensive lab and field testing, The North Face is proud to introduce the first apparel made from the brand’s proprietary, FUTURELIGHT™ fabric.

“Product innovation, pushing the boundaries and having the courage to disrupt have been a part of The North Face DNA since our company was founded over 50 years ago,” Scott Mellin, Global General Manager of Mountain Sports at The North Face said. “For far too long, we have been forced to adapt to our clothing and environment. With the introduction of FUTURELIGHT™, we are finally offering clothing that adapts to our needs. The introduction of this fabric is a pivotal moment for our brand, for the future of the apparel industry, and for consumers who will no longer need to sacrifice comfort or air permeability for waterproof protection.”

Wear the Future

The nanospinning process used to create FUTURELIGHT™ fabric has allowed the brand to add unmatched air permeability into the membrane of a fabric for the first time. The process creates nano-level holes, allowing for incredible porosity while maintaining total waterproofness, letting air move through the material and provide more venting than ever before.

Nanospinning also gives The North Face designers the ability to adjust weight, stretch, breathability, durability, construction (knit or woven), and texture during the manufacturing process to match both athletes’ and consumers’ end-use, activity or environment. Designers can customize the fabric for specific usage, for example, by increasing breathability in garments for aerobic pursuits or increasing protection for harsh, wet climates. The ability to adjust these factors in fabric construction and manufacturing is pushing the limits of innovation in apparel, equipment and accessories.

“We are starting with jackets and outdoor apparel, but we won’t stop there,” Mellin said. “FUTURELIGHT can theoretically make anything breathable, waterproof and for the first time – comfortable. This technology is paving the way for the future of technical fabrics and provides endless possibilities across The North Face product categories.”

With the launch of FUTURELIGHT™, The North Face is also aiming to deliver industry-leading sustainability practices through its new fabric creation process. These advances have allowed the brand to responsiblycreate three-layer garments with face and backer layers made up of 90 percent recycled materials.

Athlete Tested, Expedition Proven

ใส่ Embed code

FUTURELIGHT has been tested extensively for more than 400 continuous days by 15 members of the brand’s global athlete team, proven through use in the highest peaks and harshest environments, including the Himalayas’ Lhotse and Everest, in temperatures ranging from -50 degrees F to 60 degrees F.

While testing FUTURELIGHT™ The North Face team alpinist, Jim Morrison climbed, and skied three 8000 Meter peaks 2018, including Everest, Cho Oyu and the world’s first descent of Lhotse Couilor with his partner Hilaree Nelson.

“During the past two years, our world-class team of climbers, skiers, alpinists, snowboarders and trail runners has been rigorously testing FUTURELIGHT across every discipline to prove this technology in varying weather conditions and climates all over the world,” Nelson, The North Face athlete team captain, said. “In all my years in the mountains, I’ve never experienced a product that moved and performed as well as FUTURELIGHT. It is creating a new paradigm for what I expect out of a waterproof material.”

Beyond The North Face athletes and internal testing labs, the brand worked with third-party independent experts including UL, a world-renowned safety science organization, to push the limit of the FUTURELIGHT fabric. UL tests waterproofing for the National Fire Protection Association (NFPA), an organization that certifies first responder gear for firefighters, EMS and hazmat responders.

The launch of FUTURELIGHT will also be celebrated through an event open to the public on October 1 in New York City.

FUTURELIGHT Jackets, Pants and Bibs will be available exclusively on The North Face selected stores beginning October 1, 2019. For more information visit www.thenorthface.com/featured/futurelight.

ABOUT THE NORTH FACE®

The North Face was established in 1966 and provides athletes with professional equipment for a range of outdoor activities. The name The North Face is derived from the coldest and most difficult climb on the northern sierra. The image is sourced from Half Dome, a mountain in Yosemite National Park. In 1997, The North Face adopted the slogan, “Never Stop Exploring” — a phrase that embodies the spirit of travel and has become the brand’s trademark motto.

As the leading global brand for outdoor sports, The North Face is constantly experimenting in creating products that meet the needs of users to help them explore the world and challenge the limits of human potential. Furthermore, the brand has always been committed to protecting the environment, reducing the eco-footprint of humans through various sustainable development initiatives. The North Face products are available in professional sports retail outlets around the world.